Three-side-seal packaging bags and back-seal bags are very different from the requirements of packaging machine loss according to the shape and weight of the packaging content. The three-side sealing bag, as the name implies, is to seal the three sides of the packaging bag, and load things from the top seal, while the back-seal bag encapsulates the plastic packaging from the middle. The following description of the bag method is based on the packaging mechanism of the two The difference:

1. Back seal bag

Back-seal bag, also called middle-seal bag, is the vocabulary of the packaging industry. Simply put, it is a packaging bag with edge-sealing on the back of the bag. Back-seal bag has a wide range of applications, such as general candy, bagged instant noodles, bagged dairy products, etc. All use this type of packaging.

Compared with other packaging forms, back-seal bags have no edges on both sides of the bag body, so the pattern on the front of the package is complete and more beautiful. At the same time, in the layout design, the bag body pattern can be designed as a whole, which can maintain the continuity of the picture. And because the seal is on the back, both sides of the bag can withstand greater pressure, reducing the possibility of package damage. Moreover, the packaging bag of the same size adopts the form of back seal to seal the smallest total length, which also reduces the probability of seal cracking in a certain sense.

In terms of material, back-sealed bags are no different from general heat-sealed bags. In addition, composite packaging such as aluminum-plastic and aluminum-paper is also widely used in modified packaging. The most common forms of packaging are milk packaging in bags and melon seed packaging in large bags. Back-seal bags also have requirements for the weight of the contents, and should not be too heavy, within 10KG.

Back-seal bags can be used as food bags, and also play a role in the beauty packaging industry, preventing moisture, water, insects, and preventing things from being scattered. Adapt to the packaging requirements of different types of products.

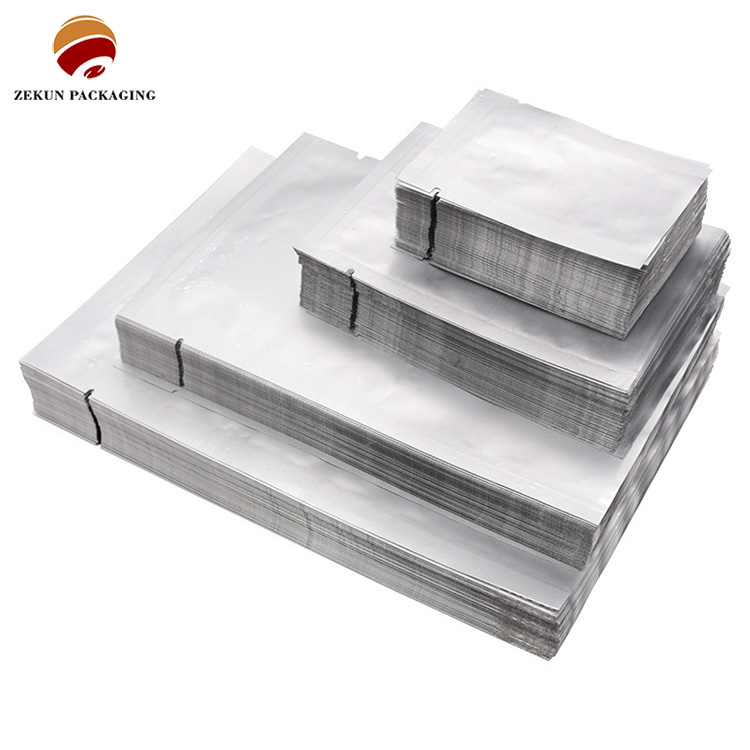

2. Three-side sealing packaging bag

Three-side sealing bag, namely three-side sealing, leaving only one opening for the user to install the product. Three-side sealing bags are the most common way of making bags. The side-sealed bag has the best airtightness, and it is usually necessary to use this bag making method to pull out the real bag.

The main products and characteristics of the three-side sealing bag: plastic food packaging bags, vacuumized nylon bags, rice bags, upright bags, zipper bags, aluminum foil bags, tea bags, candy bags, powder bags, rice bags, cosmetic bags, facial masks and eye masks Bags, medicine bags, pesticide bags, paper-plastic bags, bowl surface sealing film, special-shaped bags, anti-static bags, film rolls and plastic bags for automatic packaging machines. Used for sealing packaging of various consumables such as printers, copiers, etc.; and other bottle sealing films of various conventional materials.

The compound three-side sealing plastic bag has good barrier properties, moisture resistance, low heat sealability, high transparency, and can also be colored by color printing. Commonly used in daily necessities composite packaging bags, cosmetic composite packaging bags, toy composite packaging bags, gift composite packaging bags, hardware composite packaging bags, clothing composite packaging bags, shopping mall composite packaging bags, electronic product composite packaging bags, jewelry composite packaging bags, sports Precision packaging of products in various industries, such as equipment composite packaging bags.

Three-side sealing bags need to be vacuum packed in many cases, and the requirements for use are also very diversified.

Yes, food, cosmetics, industry, etc. can all be involved. The first production process meets most bag-making requirements and reduces loss. It can be used for bag-making machines with small or large door widths, mainly due to the size of the quantity. The three-side sealing bag is to prevent food from spoiling. In order to make the shelf life longer, vacuum packaging is mainly to extract all the air in the bag and then seal it, so that the bag is always in a high-pressure state to reduce the growth of bacteria. Customers can also do it by themselves. Sterilization treatment.

The three-side sealing bag making method has low loss, the temperature is adjusted by PID, adjustable from 0 to 300℃, non-contact automatic control, and centralized setting of man-machine interface. Custom-length bag making, photoelectric tracking bag making. The punching method can be set to continuous, interval, stop, and the punching time can be preset. The double delivery method can be one to six times delivery. The advantages of the packaging machine improve the product grade. The three-side sealing bag has excellent sealing performance, high barrier degree, ultra-low oxygen and moisture permeability, moisture-proof, pollution-proof, radiation-proof and anti-corrosion, strong mechanical properties, bright and practical appearance, non-toxic, and tasteless in line with national standards. It has the characteristics of easy loading and unloading, stacking, handling and storage.

In contrast, the three-side seal bag can be distinguished from the back seal bag at a glance in the edge sealing process, and the three-side seal bag does not have the back seal edge. When in use, the three-side seal bag has better air-tightness and can be used as a food packaging bag that needs to be vacuumed. It can prevent food from spoiling and extend the shelf life of the food; at the same time, the use of the three-side seal bag can reduce packaging materials Attrition rate.

Three-side-sealed packaging bags and back-sealing bags have their own advantages, and Zekun Packaging can fully meet its production process requirements.

No comment yet, add your voice below!